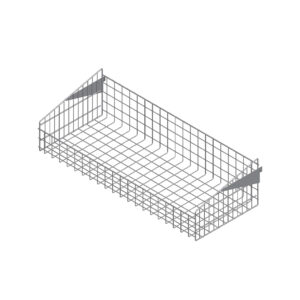

The 2 x bent wire shelf, due to its high strength, is designed for displaying heavier articles. The increased load carrying capacity is due to the way the shelf is made and the materials used, in the form of flat bars and wires with larger diameters. If the shelf is to be used for displaying lighter goods, only wires can be used instead of flat bars. The shape of the shelf, especially the bend in it on both sides, prevents goods from falling off. The use of a shelf allows the rack to function without the need to install a back, but in order to stabilize the rack, it is necessary to install a connector. Thanks to the welded brackets, the assembly of the shelf is done by placing it directly into the rack legs, which definitely speeds up and simplifies the process of assembling the rack. Depending on the customer’s needs, brackets with additional laser-burned teeth can be used to produce the shelf, which allows the shelf to sit at an appropriate angle, such as 60 degrees.

The production process of the 2 x bent wire shelf begins with the welding of wires of the appropriate diameter using automatic welding machines. Then, to guarantee the safety and aesthetics of the product, the protruding ends of the wires are cut off using semi-automatic wire cutters. During the trimming process, product quality control is carried out. The next step is to bend the wire mesh on a press brake on both sides, which prevents goods from falling off both the front and back sides of the shelf.

The final stage of production is the application of a suitable coating to the shelf, the selection of which should depend on the purpose of the rack. Thanks to the application of a double coating, ie. zinc primer, followed by a final paint in a color chosen by the customer from the RAL palette, the shelf is resistant to corrosion and rusting, making it possible to locate the entire rack outside the building.