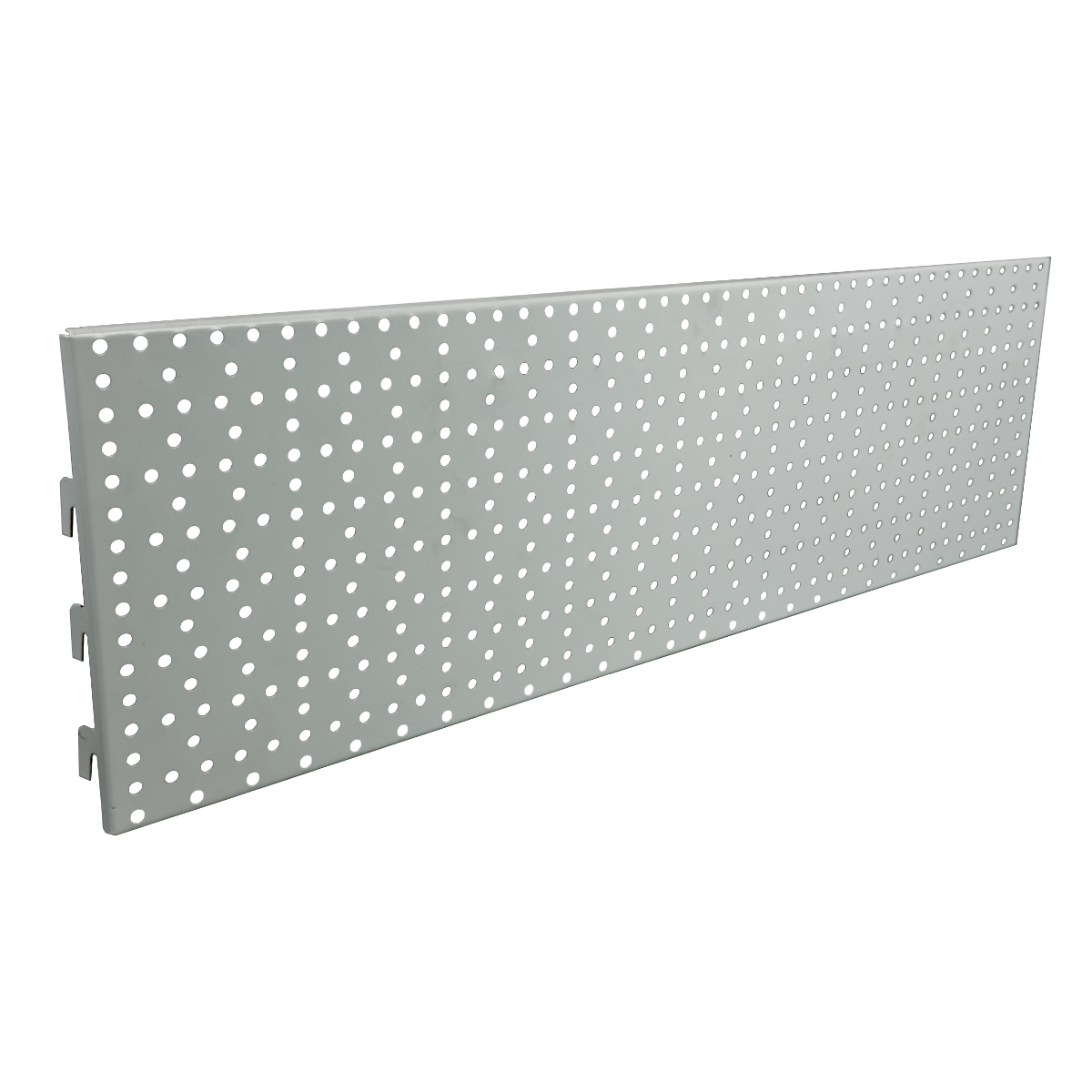

Perforated sheet metal is a popular material used in a wide variety of applications, including the manufacture of system shelving. The perforated sheet is ideal for store shelving and can be positioned as the back (back) of the shelving, so there is no need for an additional connector.

The perforated metal back performs a number of important functions. First of all, it plays the role of preventing the objects stored on the rack from falling off. It prevents items from falling out through the back, making the metal rack safer to use.

In addition, thanks to the perforated structure of the sheet metal, it is possible to mount hangers on which to hang tools or other accessories. This makes the bookcase more functional and allows for better organization of stored items.

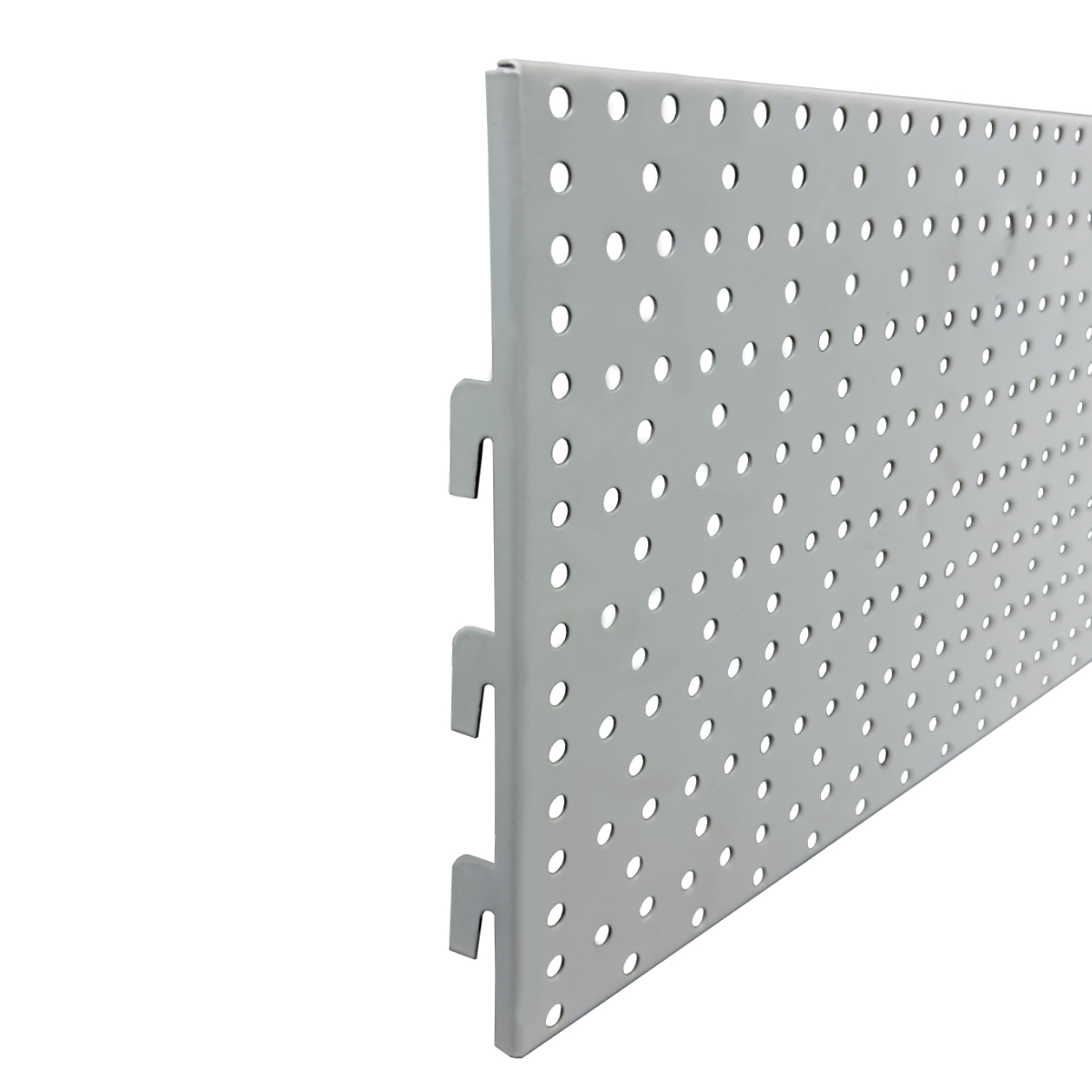

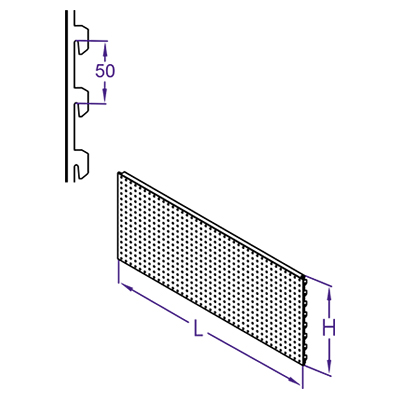

The back is made of laser-cut 0.8-mm-thick sheet metal, but depending on the customer’s needs, it is possible to use sheet metal of greater thickness. The sheet metal is then properly bent on a press brake, ensuring that the back of the rack is rigid. The laser-cut brackets located on the sides of the sheet are used for its smooth installation in the holes (perforations) of the rack leg.

Perforated sheet metal is also lightweight yet strong, making it an ideal material for shelving applications. It is resistant to corrosion and easy to clean, which allows you to keep the rack in good condition for a long time.